wholesale Evaporation Residue Testing|100 degree evaporation residue : department Store The NaOH they add to it is to prolong shelf life. And the reaction by which sodium hypochlorite is reduced to sodium chloride consumes protons, producing even more hydroxide, so it's indeed possible that residual alkali is . WEB9 de jun. de 2023 · Welcome to the community for fans of the Goddess Willow Ryder 👸🏽💜 A rising star in the adult industry, and already a legend for her riding skills 🏇😮💨 Check out her .

{plog:ftitle_list}

WEBKim Possible. Kim Possible é a típica adolescente que, no seu tempo livre, salva o mundo de vilões. Juntamente com o melhor amigo Ron Stoppable; o seu animal de estimação, um rato careca chamado Rufus .

Evaporation residue test is to measure the dissolved part mass of materials in different solutions. By further analysis for evaporation residue, the safety of packaging materials can be greatly ensured. Contact Us! We can help you .i-Resitest 8100 Evaporation Residue Constant Weight Tester is professionally designed for the precise mass determination of dissolved substances of table wares, containers, packaging .The Japanese Food Sanitation Act designates the evaporation residue test as a specification for plastics that intended to contact with foods. The test conditions and migration limits for oils and fatty foods were considered on the basis of the results obtained from the evaporation residue test according to the Japanese Act and the overall migration test into olive oil according to .Nonvolatile residue (NVR), sometimes referred to as molecular contamination is the term used for . However, ASTM E595-84 testing has become standard practice for assessing NVR risk. Nonetheless, good quality control to verify the space . During the manual evaporation method, the mass of the molecular residue obtained from the NVR

residue on evaporation method

100 degree evaporation solids

The NaOH they add to it is to prolong shelf life. And the reaction by which sodium hypochlorite is reduced to sodium chloride consumes protons, producing even more hydroxide, so it's indeed possible that residual alkali is . 1.1 This test method covers the determination of the amount of carbon residue (Note 1) left after evaporation and pyrolysis of an oil, and is intended to provide some indication of relative coke-forming propensities. . residue formed after evaporation and pyrolysis of a petroleum product under the conditions specified in this test method. The .

Evaporation residue test (Overall migration test) Limit: 30 μg/ml (when using heptane, PE and PP ≤ 150, PS ≤ 240, PMP ≤ 120 μg/ml ) Determination: Weigh residue of migrant after drying and heating at 105°C for 2 hr. Test condition Food Simulant Temp(°C) Time(min) Normal(pH>5) water .

3.2 This test method for residue by evaporation tends to give an asphaltic residue lower in penetration and ductility than the distillation test method (D6997).Material may be accepted but shall not be rejected as failing to meet specifications containing requirements for determination of residue by distillation, on data obtained by evaporation.

Please rest assured to wholesale or buy discount manual prtroluem product conradson carbon residue tester made in China here from our factory. . It is used to determine the amount of carbon residue of petroleum products after evaporation and pyrolysis, so as to check coke forming property of petroleum products.It can also meet requirements of .observed or calculated, expressing the result of a test or analysis, shall be rounded off in accordance with IS 2:1960 ‘Rules for rounding off numerical values (revised)’. The number of significant places retained in the rounded off . Tests on residue: t ) Residue by evaporation, 60 percent, A4in 2) Penetration25°C/ 100g/ 80-150 5 sec 3 .Solids, residue on evaporation at 105°C, total, gravimetric Parameter and Code: Solids, residue on evaporation at 105°C, total, I-3750-85 (mg/L): 00500 1. Application 1.1 This method may be used to determine the total-solids concentration of any natural or treated water or industrial waste. 1.2 Total residue represents the sum of both

1.1 This test method covers the determination of the amount of carbon residue (Note 1) left after evaporation and pyrolysis of an oil, and is intended to provide some indication of relative coke-forming propensities.This test method is generally applicable to relatively nonvolatile petroleum products which partially decompose on distillation at atmospheric pressure.

ERT-01 Evaporation Residue Constant Weight Tester is professionally designed for the precisely quantitative determination of dissolved substances of table wares, containers, packaging films, cans, tubes and other food-use equipments in different soaking solutions. . Water vapor transmission rate test by inverted cup method: Non-destructive .Going Deeper - Nonvolatile Residue - NVR Testing. While particulate contamination physically blocks openings and clearances, nonvolatile residue (NVR) causes issues through chemical means. . The Critical Role of Flash Evaporation in NVR Testing. A flash evaporator system enables key aspects of NVR testing essential for reliable and accurate . In geology there is a streak test where a mineral is rubbed on a alumina plate to create microscopic particles. The streak test often yields colors that are different than that of the "massive" specimen. . is there such case with a salt solution where hydrated salt version would not occur as the residue after evaporation, or vice versa with .MODEL : HGT 915 & 917: Gum Test; SPECIFICATION : Measure evaporation residue in aviation fuels, motor gasolines, and other volatile distillates. > The HGT 915 uses air evaporation, while the HGT 917 offers the versatility of either air or steam evaporation. > Both models are capable of testing three 100 ml samples simultaneously.

3.1 The test may be used to indicate compositional charac-teristics of emulsified asphalt. Evaporation residue may also be subjected to other characterization tests. 3.2 This test method for residue by evaporation tends to give an asphaltic residue lower in penetration and ductility than the distillation test method (D6997). Material may be .CO2 transmission rate test by weighing method: Water vapor transmission rate test by inverted cup method: Non-destructive test for packaging seal performance: Multi-station packaging pressure test: Tensile test of packaging . 3.2 This test method for residue by evaporation tends to give an asphaltic residue lower in penetration and ductility than the distillation test method (D6997).Material may be accepted but shall not be rejected as failing to meet specifications containing requirements for determination of residue by distillation, on data obtained by evaporation.

100 degree evaporation residue

The TOC vials were placed open under an extractor hood to assist evaporation without inputting external contamination. Despite all these precautions, and in order to take account of potential carbon contamination appearing during sample evaporation, sample blanks were also prepared and left to evaporate beside the test samples.

The term “SAP” in the context of acetic acid glacial testing likely refers to the “Saponification Value” or “Saponification Acid Value.” The Acetic Acid Glacial Testing Procedure (SAP) saponification value is a measure of the average molecular weight of all the fatty acids present in a substance. It is often used in the analysis of fats and oils. 1.1 This test method covers the determination of dissolved organic and inorganic matter and colloidal material found in high-purity water used in the semiconductor, and related industries. This material is referred to as residue after evaporation (RAE). The range of the test method is from 0.001 μg/L (ppb) to 60 μg/L (ppb).

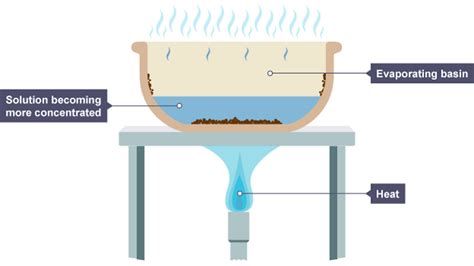

Residue on Evaporation Test (water analysis) : Evaporate 100 ml to dryness on a water bath and dry to constant weight at 105°C. The residue weighs not more than 1 mg (0.001%). Heavy Metals Test (water analysis) : Determined by Method D on 12 ml of a solution prepared in the following manner.

Cooling and weighing the residue: After evaporation, the dish is allowed to cool to room temperature in a desiccator and then re-weighed to determine the weight of the nonvolatile residue. Calculation: The nonvolatile matter content is calculated by dividing the weight of the nonvolatile residue by the weight of the original sample and .Cleaning validation procedures are carried out in order to assure that residues of cleaning agents are within acceptable limits after the cleaning process. Cleaning agents often consist of a mixture of various surfactants which are in a highly diluted state after the water rinsing procedure has been completed. This makes it difficult to find appropriate analytical methods that are sensitive .Also, that centripetal force will keep the solution spread out over the walls of the flask. That will maximize the surface area of the liquid, maximizing the rate of evaporation. Third, rotary evaporators have a water bath that allows the solution to be warmed. This capability offsets the fact that evaporation is an energy-consuming process.CO2 transmission rate test by weighing method: Water vapor transmission rate test by inverted cup method: Non-destructive test for packaging seal performance: Multi-station packaging pressure test: Tensile test of packaging materials with ultra-long elongation: Heat-seal strength test for cap films of medical bottles, yogurt cups and jelly cups

In testing both hardware brand and artist’s brand evaporation of turpentines, I measured from 1 to 2 % (by weight) residue left behind after evaporation. This residue was very sticky to the touch. From what I understand, this resin does becomes integrated into the polymerized oil film matrix.1. Calculate the percentage of residue for each sample, as follows: Residue, % = 4 × (M a -M b) where: M a = Weight of the container and asphalt emulsion residue in grams, and M b = Tare weight of the container in grams. F. REPORTING OF RESULTS Report the percentage of residue by evaporation as the average of the three results. G. PRECAUTIONS

Resultado sorteio ano letivo de 2024. 8 de novembro de 2023 8 de novembro de 2023 gr8. A lista de sorteados está disponível em cepmgo.gr8.com.br, na opção RESULTADOS. Destaque, Notícia. permalink. Navegação da Postagem. Inscrições Processo seletivo 2024.

wholesale Evaporation Residue Testing|100 degree evaporation residue